LW-I500 Tsis Siv Neeg Rebar Threading Tshuab

Lus piav qhia luv luv:

Kev ua tau zoo thiab kev siv

LWⅠ―500 Hom Rebar Threading Tshuab yog siv rau lub tsev rebar kawg

xov ua ntawm ib hom tshiab ntawm ntau lub hom phiaj.Nws tuaj yeem siv rau Rib

peeling thiab dov threading tshuab, Directly dov threading

technology, BDC-2Steel Bar Threading (Txiav) tshuab thiab lwm yam.Qhov ntau ntawm

Kev ua haujlwm yog los ntawm Φ12 txog Φ40, qhov pib npog tag nrho cov hlau txuas qhov ntau thiab tsawg ntawm

tam sim no.

Ntu Ⅱ. Tseem ceeb

Thaum siv rib tev thiab dov qauv, tus tav tev qauv yuav

ua ntej tev tawm ntawm transverse thiab longitudinal tav ntawm rebar yuav dov pa

rt, tom qab ntawd siv lub taub hau dov los dov cov xov, lub rebar yog ntsia rau hauv a

daim npav kom ua tiav cov txheej txheem ntawm rebar xov.Thaum siv BDC-2Steel Bar Thr

eading (Txiav) qauv, nws yog ncaj qha hloov lub rib peeling riam cuab yeej txiav kn

ife cuab tam, ces ua cov xov ntawm lub upsetting rebar ib feem.

Ntu Ⅲ. Lub tshuab nta

1. Nruab rau hauv ib daim npav kom ua tiav cov tav tev, dov xov, ceev ceev processi

ng ceev, qib siab ntawm automation, kev ua haujlwm yooj yim.

2.Innovation ntawm cov qauv ntawm stripping tav txoj kev du ua haujlwm, st

ripping rib nto yog du, zoo hom xov dov, siab precision, goo

d txoj kab uas hla loj sib xws.

3.Knife Tool installation ceev thiab yooj yim, nrog tshwj xeeb ntsuas,

los xyuas kom meej cov txheej txheem sib xws. Optimization tsim tuaj yeem ua cov cuab yeej nrog si

mple sib tsoo tom qab rov siv dua, txuag cov ntaub ntawv txiav cov cuab yeej. Los ntawm qua

ntitative hloov cuab tam txoj hauj lwm sib txawv me me workpieces tuaj yeem pom tau.

4.Hydraulic cov cuab yeej tau txais yuav kom paub tias tsis siv neeg clamping workpie

ce thiab cia li kaw, riam, nyab xeeb thiab txhim khu kev qha, txo cov kev siv zog ua haujlwm

ntawm cov neeg ua haujlwm. Ua los ntawm high quality linear phau ntawv raws li ib tug motion mechanism, ua

lub workbench thiab clamping mechanism ntawm kev ua haujlwm yooj yim, txhim khu kev qha, txo

s cov neeg ua haujlwm siv zog ua haujlwm, thiab tuaj yeem ua kom cov machining raug.

3

5.Nws tuaj yeem ntsia tau cais stripping tav dov, dov taub hau, proc

ess ntawm kev ua cov sib txawv ntawm cov hlau taub hau kev ua haujlwm, yooj yim hloov ib qho

d ua tiav lub hom phiaj ntawm ib lub tshuab. Ua lub tshuab ua tus qauv ntaus ntawv yog

ruaj khov thiab txhim khu kev qha, kev ua haujlwm yooj yim, tsim nyog tus nqi, thiab kev sib xyaw ua ke

ntawm cov cuab yeej siv tshuab.

Ntu Ⅳ. Tshuab tshuab parameters

Daim duab 1 Machine technology parameters

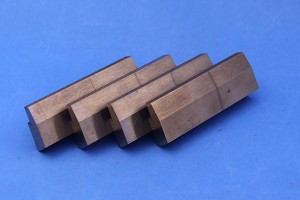

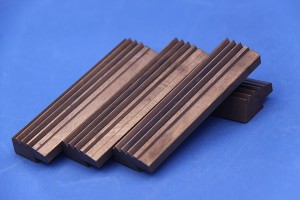

Ntu Ⅵ. LW Ⅰ―500 Hom Rebar Threading Tshuab sketch map

Tshuab Hom LWⅠ―500 Hom Rebar Threading Tshuab

Tshuab Luj (Kg) 1200

Lub cev muaj zog loj (KW) 5.5

Dej twj tso kua mis lub cev muaj zog (KW) 0.15

Ua haujlwm voltage 380V, 50Hz

Cov zis ceev reducer (RPM) 62

Zuag qhia tag nrho qhov ntev (mm) (Length * Dav * Qhov siab) 1700 * 1000 * 1400

0086-311-83095058

0086-311-83095058 hbyida@rebar-splicing.com

hbyida@rebar-splicing.com