BDC-Auto H1 Rebar End Upset Forging Machine

Short Description:

Features

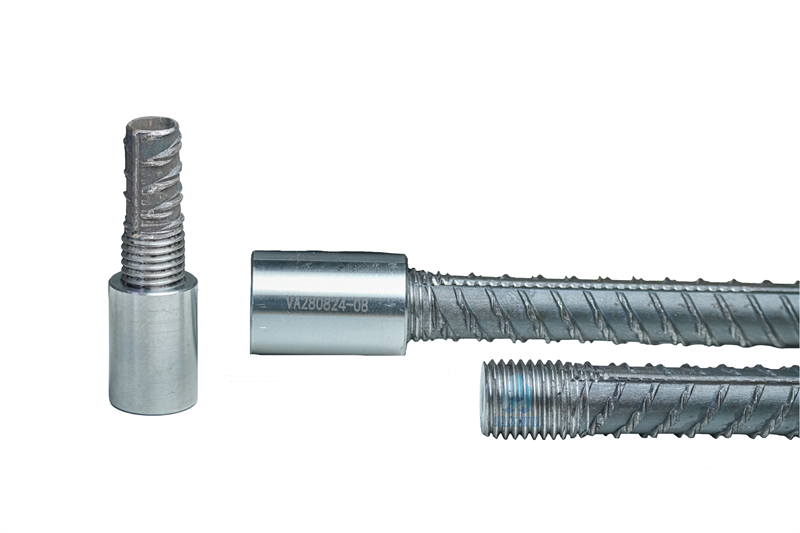

●To enhance the tensile strength of the rebar base material without damaging its mechanical properties, this machine adopts a room temprature extrusion deformation process.

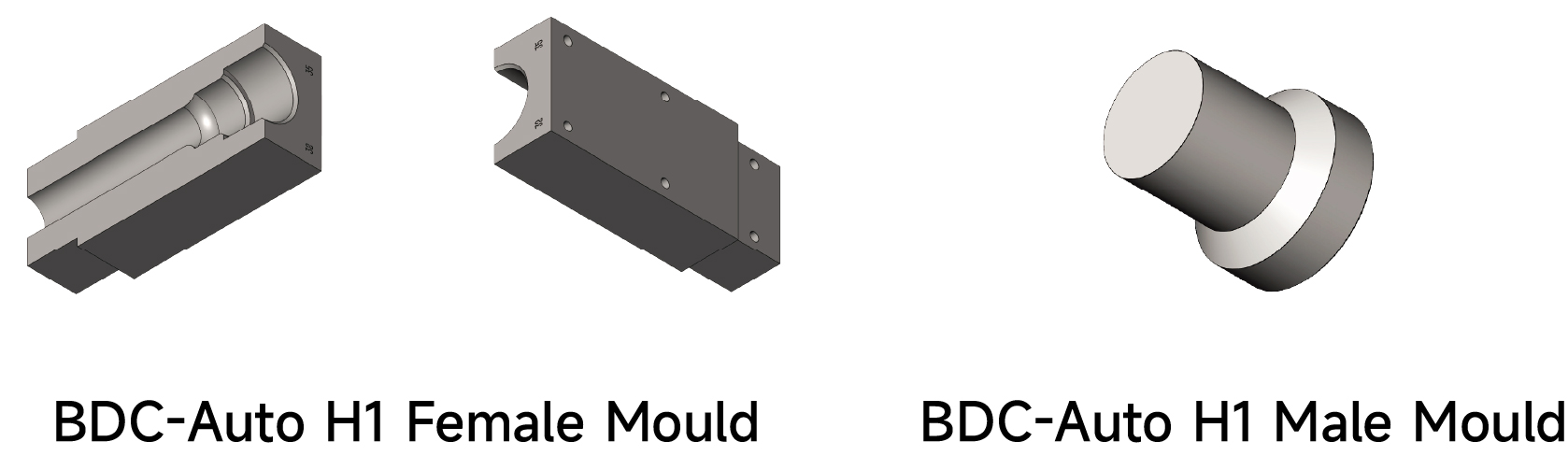

●In terms of machine structure, the design is compact and occupies minimal space. It uses a high-flow plunger pump to supply oil to the working cylinder, significantly improving work efficiency. The design also strengthens the rigidity of the working cylinder, die cavity, mold, and guide pillars to ensure the machine's long-term stable operation.

●A shock-resistant electric contact pressure gauge is used to control the upsetting working pressure and automate the upsetting process, making the process more convenient and reliable. The clamping jaws and die cavity are integrated, reducing the machine's overall size and eliminating additional clamping mechanisms, effectively ensuring the coaxiality of the upset portion and the base material, which improves process quality and stability.

|

BDC-Auto H1 Main Technical Parameters |

|

|

Rebar Processing Range |

16mm-40mm |

|

Main Motor Power |

7.5kW |

|

Power Supply |

380V 3Phase 50Hz |

|

Rated Pressure |

31.5MPa |

|

Piston Stroke |

120mm |

|

Machine Weight |

1130kg |

|

Dimensions |

1300mm×1000mm×1400mm |

0086-311-83095058

0086-311-83095058 hbyida@rebar-splicing.com

hbyida@rebar-splicing.com